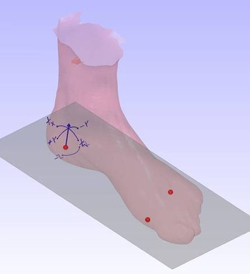

Computer modeling can determine the best design for orthopedic insoles. Courtesy of Delcam.

Latest News

October 24, 2012

Additive manufacturing (AM) is not only proving to be a boon for rapid prototyping and custom consumer goods, but also for doctors and the medical industry as a whole. It seems like every day that another healthcare professional discovers a new way to use 3D printing for the benefit of patients. It’s been our privilege here at Rapid Ready to cover some of these stories.

Often you can tell something is a good idea when the end result seems so obvious you can’t believe no one else thought of it. Leveraging the power of AM to create custom orthopedic insoles is one such idea. Not only does the technology almost beg to be used for the manufacture of insoles, AM also reduces the cost of custom insoles, and makes tweaking the end product much simpler.

Researchers at Glasgow Caledonian University are using motion sensor cameras to determine the exact measurements required for an insole. The data is then used to create a 3D image, which is translated into a physical product using AM. The process of creating custom orthopedic insoles used to take up to six weeks. A 3D printer can replicate the feat in the same day a patient visits a doctor.

“We want to make these products specifically for the patients’ own impairment and walking difficulties,” said Glasgow Caledonian University Professor Jim Woodburn. “The most exciting part of the project is that the computer design is then transferred to a 3D printer. What we have is complete control of the manufacturing process.”

As is often the case with AM, the ease of building an insole led to further experimentation. The research team has begun to add coils and what amount to mesh springboards to further improve on the designs.

“The custom-made insoles really give me a lot of confidence when out walking,” Cameron Mitchell told the BBC. Mitchell suffers from rheumatoid arthritis and osteoarthritis. “I was actually going to have an injection in to my heel, and through having the insoles the injection is no longer necessary because the swelling has gone down so significantly. It has saved me being in plaster for a fortnight.”

This new procedure has the potential to affect around 200 million sufferers in Europe alone. The European Union has given Mitchell a £3 million grant for continued research.

Below you’ll find a video about the research.

Source: BBC

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE