Solidscape Announces 3Z Pro

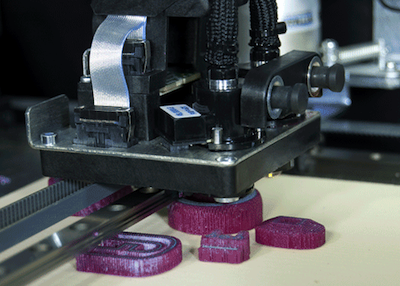

An inside view of the 3Z Pro. Image courtesy of Solidscape.

Latest News

July 11, 2012

Each new 3D printer is an example of how the industry is developing. Each new design brings either a fresh approach to additive manufacturing (AM) or an improved iteration of an already existing process.

Solidscape, a Stratasys company, has announced the release of its newest 3D printer, the 3Z Pro. This particular system continues the use of Solidscape’s drop-on-demand (DOD) thermoplastic ink-jetting technology, along with precision milling of each layer. For those unfamiliar with Solidscape, the company’s process is mainly used to create objects for lost-wax casting/investment casting and mold making applications, using a wax-like material.

The 3Z Pro targets vertical industries that require the need for high precision, close tolerance or complex geometries for critical applications such as aerospace, automotive, jewelry, consumer products and electronics, dental, education, medical (mainly orthopedic), small precision casting, sporting goods and toys.— Bill Dahl, Solidscape director of marketing & communications

The 3Z Pro is a desktop printer, weighing in at 80 lbs. and with a 21.4 x 18 x 16 in. (558 x 495 x 419 mm) footprint. It has a build envelope of 6 x 6 x 4 in. (152.4 x 152.4 x 101.6 mm), with a resolution of 5,000 x 5,000 dpi (197 x 197 dots/mm) and an accuracy of ±.0254 mm.

Material for the printing process is loaded into the machine via solid bars, about the size and shape of an over-sized crayon. According to the company, the 3Z Pro automatically constructs support during the build process, without relying on CAD designed support structures. The support material can later be removed, hands-free, through use of a liquid solution.

“Our technology enables us to print with two materials, build and support. Our support is a dissolvable, sacrificial material that allows us to create geometries of any complexity,” says Dahl. “The customer benefit is that they can avoid time-consuming additional CAD design and support structures needed by other technologies while eliminating the time and risk of removing support structures at the end of jobs. The build material is 100% castable with no material shrinkage.”

The new system uses Solidscape’s 3Z Works software and accepts .stl and .stc file formats. The 3D printer includes a touchscreen with language neutral icons, offers wireless connectivity, and has self testing and auto-calibration functions.

“These enhancements are the direct result of feedback we receive from our loyal customers, and it will allow companies to become more self-sufficient in their direct manufacturing endeavors,” said Fabio Esposito, vice president of worldwide sales and marketing for Solidscape. “Operators only need to refill materials and replace the build plate, similar to what they already do with their home printer.”

The manufacturer’s suggested retail price for the 3Z Pro is $45,650.

Below you’ll find a video about the 3Z Pro.

Source: Solidscape

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE