Freehand Laser Cutter Offers Possibility for Subtractive Rapid Prototyping

Freehand laser cutter developed at the Hasso Plattner Institute. Courtesy of

July 20, 2012

The majority of what we cover here at Rapid Ready is based on additive manufacturing (AM) technology, but that doesn’t mean we don’t try to keep an eye on the subtractive field as well. We covered one possible contender in the subtractive field here and today we present another possibility.

The name of the game in prototyping these days is speed. It’s no accident that we include the “rapid” half of rapid prototyping in our name. Working in collaboration with colleagues Stefanie Mueller and Pedro Lopes, Patrick Baudisch from the Hasso Plattner Institute in Potsdam, Germany has created a freehand laser cutter technique that can quickly produce prototypes.

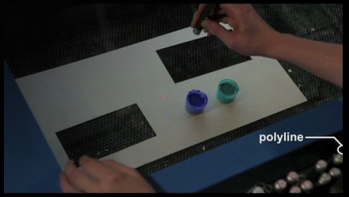

The system uses differently colored laser pointers and a camera mounted above the work surface to track cuts. A computer translates what has been captured by the camera and proceeds to instruct a laser cutter on where cuts are to be made. Shapes can be added by use of different colors and different techniques.

Each laser pointer includes a sensor (the colors mainly act as visual reminders for human users) that tracks operations. One laser pointer can be specified to produce circles with a few gestures, while another can add shapes, such as teeth for gears or finger joints. The whole process is as fast as the operator can draw and the laser and the cutter can fabricate.

“The 3D printer takes hours. With the laser cutter I can have an object in seconds — it’s insanely fast,” said Baudisch. “By the time my 3D printer has produced the first object, I have iterated so much [using the laser cutter] that I have developed an entirely different approach to the problem — that has huge implications for the creative process.”

At this point in its development, the system is restricted to cutting plywood, but I doubt that will remain true for long. It really isn’t that big of a jump to move to other materials that are capable of being cut quickly and precisely with a laser cutter. While I’m not sure this is any sort of replacement for most uses of AM in rapid prototyping, it could find a niche in conceptual design or in fields that don’t require complex prototypes.

Below you’ll find a short video of the system at work.

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE