Objet Pushes Forward with Multi-material Printing

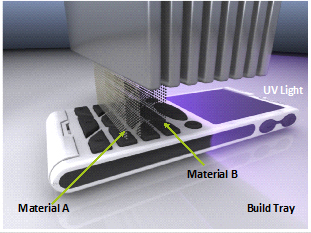

Objet’s multi-material process. Courtesy of Objet.

Latest News

June 20, 2012

Different 3D printer manufacturers use different methods to improve their products. Some work on designing larger build envelopes, others seek to hone a flagship process. To paraphrase The Graduate, Objet (company profile) has one word for you: materials.

Certainly the company is always looking to improve its product lines, but much of the foundation on which the company is building its future is based on its range of materials. Upcoming mergers not withstanding, Objet is continuing to develop new ways its materials can be used, particularly when it comes to multi-material printing.

Our goal is to allow designers to better replicate their end product in the prototype stage better than any of the other technologies out there. –Bruce Bradshaw, director of U.S. marketing for Objet

Objet calls the procedure of combining materials, “Digital Materials.” According to the company, customers have the option of 17 base materials and 90 digital materials, bringing the grand total of available materials to 107. I’m fairly certain no other manufacturer can offer that many options.

The number of materials offered has been inflated recently by the development of 51 new digital materials created by combining the bases of VeroWhitePlus and the full complement of Objet’s rubber-like materials. The results include 20 rubber-like digital materials with a wide Shore scale values that range from 40-95. The company says applications for the new materials include medical and artistic purposes.

Along with offering varied material options in a single prototype, Objet says that the multi-material approach can also be used to build multiple prototypes — all with their own material composition — simultaneously. Companies looking for the ability to concurrently produce a number of smaller prototypes are able to do so, saving development cycle time.

Not content with offering many, many more material options than other companies, Objet is continuing development of new options.

“As a company, that is our focus. About 25% of the company’s employees are based in engineering,” said Bradshaw. “A large focus of Objet R&D is on developing new materials. It’s really what sets us apart from the competition.”

Below you’ll find a video featuring the capabilities of Objet’s Connex line of multi-material printers.

Source: Objet

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DERelated Topics