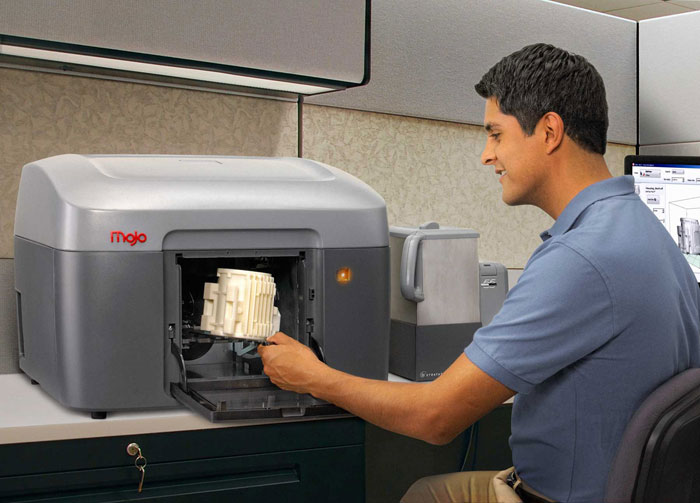

Stratasys Reveals its Mojo 3D Printer

Stratasys’ Mojo 3D printer.

Latest News

May 8, 2012

It was like an episode of Mission Impossible.

On April 11, about a dozen journalists, myself included, were instructed to fly into Minneapolis St. Paul International Airport. There we would meet a driver who would transport us to Stratasys’ headquarters in Eden Prairie, MN. We didn’t know why, and we were sworn to secrecy … until now.

The cat was let out of the bag in a conference room in the lower level of Stratasys’ main office. That cat’s name is Mojo. It’s a $9,900 professional grade 3D-printing system. By “system,” I mean it breaks the $10,000 barrier even when purchased as part of the Mojo 3D Print Pack, which includes the printer, material, support material, and support-removal system. Stratasys calls it the lowest-priced professional-grade 3D-printing system on the market, but if that’s still too much for you the company offers a leasing option with payments as low as $185 a month.

The “bag” was a white plastic cover that hid the 3D printer and the laptop it was connected to. There was no Ethernet cable sticking out from the cover because the Mojo is not a network printer. It connects to a host computer via USB, much like an inkjet printer. Files can be processed on other computers using Stratasys’ Print Wizard software, and then sent to the Mojo-connected computer for printing.

Mojo uses Stratasys’ Fused Deposition Modeling (FDM) technology, just like the company’s uPrint and Dimenson 3D printers, as well as its Fortus 3D production systems. So it’s a lower-cost 3D printer built for professional use. That’s news to be sure, but why all the cloak and dagger? Turns out there was more to Mojo.

In addition to the price, the other big reveal was the ease of use. CEO Scott Crump was inspired to invent FDM by watching ink plotters and wondering what would happen if they were extruding molten plastic, not ink. Now Mojo has taken a cue from inkjet printers with what Stratasys calls a QuickPack Print Engine. The print engine and material are all in one package. You simply drop the model material and support material packs in, snap in the print heads like you would on an inkjet printer, and you’re ready to go.

Mojo keeps it simple by taking a potential maintenance variable — the print head — out of the equation. The print head is simply replaced and recycled every time new material is added.

That material is Stratasys’ ABSplus thermoplastic. The Mojo prints it, and only it, in ivory. For the price, that’s not surprising. For about $10,000 more, customers who need multiple colors can step up to the uPrint SE Plus line of 3D printers.

More Secrets Revealed

After a recap of the company history by Crump, an overview of the market by John Cobb, vice president of Global Marketing, a demonstration by Mary Stanley, 3D Printing Product Manager, and a factory tour, we got down to brass tacks.We discovered Todd Grimm, president of TA Grimm & Associates, was given a mission of his own. In my mind, Stratasys had locked him in a room with a Mojo. The only way out was to use it to 3D print his own key. OK, my mind might have wondered a bit there. Here’s how Grimm tells it:

Mojo 3D Print Pack Specifications

|

“I spent two days with the machine. I was literally dropped off in an office with a box. I was unsupervised, unguided, unmonitored, and no instruction was given. I was told here it is, do with it what you want. Treat it like as if you’re a brand new user who just bought this system.”

Grimm put the printer through its paces, from unboxing to documentation to printing benchmark parts and judging its quality.

Here are his findings:

- In 30 minutes, he was ready to print. He had the printer unpacked, the material and support material loaded, the modeling base inserted and the software installed.

- It took him about 15 minutes to read the documentation and process the part, that includes 49 seconds to bring the part into Print Wizard, and then set the support structure and orientation to be ready to print.

- No manual calibration of the 3D printer is needed.

- The included Print Wizard software scales parts automatically if they are too large for the build envelope. It also automatically expands print jobs as needed to print multiple models, and processes all jobs with one mouse click.

- The Control Panel, which resides on the host computer and not the 3D printer, requires no instructions. It shows the amount of support and model material in the machine, as well as the estimated print time.

- It took Grimm 2 minutes and 37 seconds to boot up the printer from a powered off state and 10 minutes for Mojo to begin building a part.

- Printing was a quiet “non-event.”

- The build quality, at a layer resolution of .007, rivals that of the uPrint, Dimension and Fortus, according to Grimm.

- For simplicity, Mojo uses only a solid fill style, Grimm said. That means no honeycomb structure is used inside “solid” parts like other 3D printers use to reduce material use and build time.

- The WaveWash 55 Support Cleaning System (which bares a passing resemblance to a designer coffee pot) requires no plumbing as it heats and agitates the part to remove the soluble support material. It took about two hours to dissolve all the supports on Grimm’s benchmark part.

“Mojo is an exceptionally priced package,” Grimm said. “The $9,900 for everything included is impressive. The only thing that caused me to stop and ask, did I like it, is the 5x5x5 in. build envelope.”

According to Stratasys’ Stanley, 80% of 3D printed parts fall within that size of a build envelope. The company had end users — including its RedEye digital manufacturing service customers — independently surveyed to come up with that data.

During his presentation, Grimm said he accepts that conclusion. He expects Mojo to increase marketshare for Stratasys.

The size of that market is impressive. According to Cobb, there are 5 to 7 million commercial engineering CAD seats, more than 7 million educational CAD users and more than 6 million CAD users in architecture, engineering and construction.

Compare those numbers with the number of professional 3D printers sold — around 50,000 — and it’s easy to see why Stratasys is focusing on the professional market. That’s not to say it won’t sell to the hobbyist/maker market, but Cobb says Stratasys has no plans to target Mojo marketing to anyone other than professional CAD users.

Top Secret Kept

During the demonstration in April, the yet-to-be-announced Stratasys-Objet merger news was on a need-to-know basis. There were some rumors about Objet looking for a buyer, and HP was even mentioned. But Rapid Ready Tech chose not to report on the rumor.Speaking of HP, the company does sell a DesignJet 3D branded version Stratasys’ uPrint, but the distribution agreement will not include Mojo.

“It will be launched as a worldwide Stratasys product only,” said Cobb. “The two companies will continue to work together. HP will continue to sell their DesignJet 3D Printer (built by Stratasys) in the eight European countries as they have previously.”

It sounds to me like the idea was broached, as Cobb said there were some features that HP wanted in a product that were not available in the Mojo “at the time of launch.”

When the HP-Stratasys distribution agreement was first announced, many industry watchers thought it might be the boost 3D printers needed to really break into mainstream offices. Thanks to its low price and ease of use, I think many may make that same prediction about Stratasys’ Mojo.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Jamie Gooch is the former editorial director of Digital Engineering.

Follow DE