Rapid Ready Roundup: Fujifilm Kiosks, DARPA’s iFAB, Arcam Titanium 2 and Proof 3D Printing is Cool

McGill University’s ice printer. Courtesy of McGill University.

Latest News

May 31, 2012

In the course of my diligent efforts to keep you good people up to date on the state of additive manufacturing, I come across many interesting news items. I’ll gather them up once every few weeks and present them in a Rapid Ready Roundup (like this one). You can find the last Roundup here.

I keep hearing word that print is dead. From what I can tell, print is merely transitioning to a different medium. Some of that is electronic, and some is via a service arrangement called print-on-demand (POD). POD allows a customer to select a book they’d like to have a dead-tree version of and have it printed just for them. This saves book space and keeps overhead low.

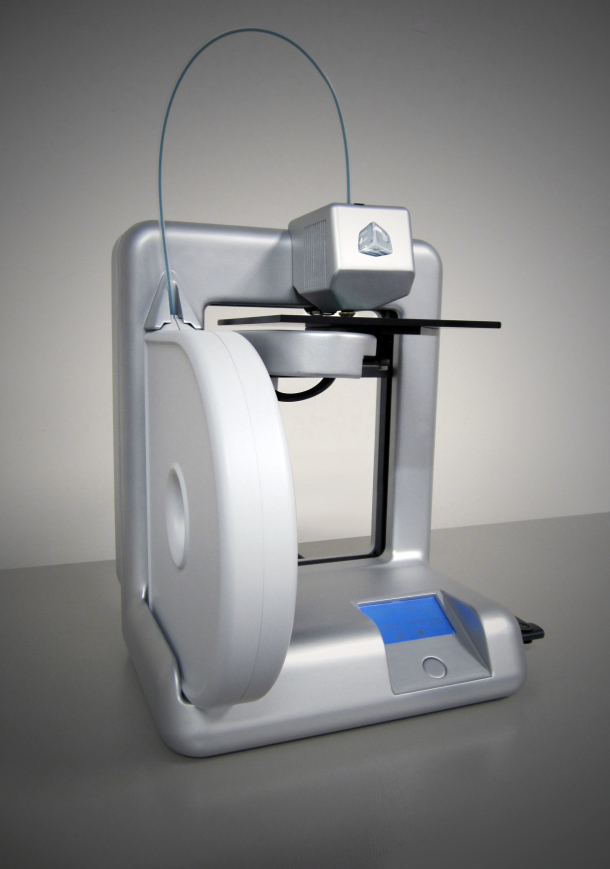

Additive manufacturing (AM) also offers a sort of POD, sometimes referred to as on-demand manufacturing. This aspect of AM offers unique products that can be one of a kind. It’s on-demand manufacturing that is driving Shapeways and other service bureaus that cater to individual customers rather than businesses. Fujifilm has a plan to bring this brand of service bureau into shopping centers.

The general plan is to create kiosks that offer customers customizable designs. A buyer will choose from a number of basic 3D designs, have them altered to fit their personal needs, and come back the next day to pick up the 3D printed product. This sort of exposure brings AM more into mainstream consciousness and gives people a chance to see what AM-created products look and feel like.

Moving from the individual consumer to mass production, DARPA is looking to create a new type of manufacturing plant. In place of the old model of defense manufacturing – in which one plant produces a single product – DARPA wants to create multi-functional facilities that are capable of producing different products based on need. This new idea is called the Instant Foundry Adaptive through Bits (iFAB) project.

The iFAB vision is to move away from wrapping a capital-intensive manufacturing facility around a single defense product, and toward the creation of a flexible, programmable, potentially distributed production capability able to accommodate a wide range of systems and system variants with extremely rapid reconfiguration timescales. – Kaigham J. Gabriel, DARPA Acting Director

The iFABs will use advanced manufacturing tools and crowd sourced designs to further defense projects, beginning with military vehicles as part of the Adaptive Vehicle Make program. Digital design and rapid prototyping are bound to be a driving force for the iFABs, which will compliment the government’s advanced manufacturing initiative.

Next up, a quick look at materials. Today we have a new material designed for electron beam melting from Arcam. Titanium Grade 2 has been developed for use in orthopedic implants. According to Arcam, “The material properties of EBM-manufactured Titanium Grade 2 comply fully with the exacting chemical and mechanical requirements in the ASTM F67 specification.” Arcam helps to build implants with osseointegration in mind, similar to the titanium jawbone created for an elderly patient in Belgium.

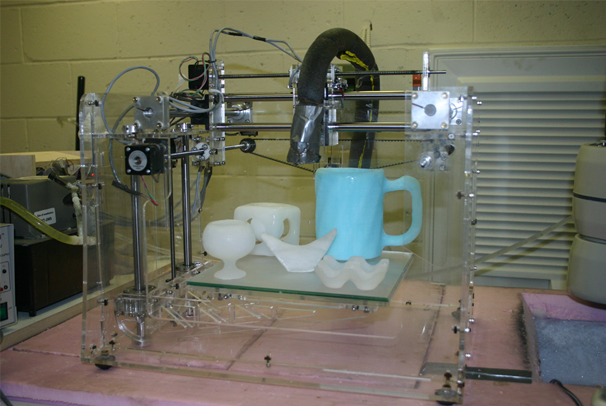

Finally, as advertised, we have proof that 3D printing is cool. Pieter Sijpkes and Jorge Angeles at McGill University are working on a 3D printer that uses ice as its medium. Other than creating really nifty ice sculptures or intricate ice cubes for that special party, the system is being looked at as a way to create metal copies from ice originals as part of a casting process.

Below you’ll find a video that touches on Fujifilm’s kiosk idea.

Sources: PCWorld, McGill University, Buy-n-Shoot, Triple Pundit, DARPA

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE