3D Printing Company Profile: Objet Ltd.

Connex 3D-printed wheel. Image courtesy of Objet.

February 13, 2012

Editor’s note: In an effort to help our readers differentiate the companies providing rapid technologies, we will be profiling them on Rapid Ready Technology. If you are a rapid technology manufacturer or service provider and would like to be considered for a profile, please contact us. Second Note: Objet has merged with Stratasys since the time of writing.

The best inventions often seem obvious in hindsight. They fill a need. Consider one of the all-time greats: the wheel. Archaeologists’ best guess is that the wheel was invented about 10,000 years ago. It’s come a long way: from solid wood construction to the introduction of spokes, to rubber tires today.

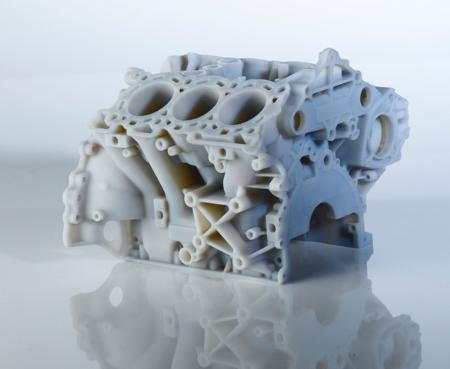

Objet Ltd. is a global manufacturer of 3D printers based in Rehovot, Israel, with a U.S. headquarters in Boston. Its multi-material 3D printing technology might also seem like an obvious invention in hindsight. Let’s say you wanted to use additive manufacturing (AM) to create a modern wheel. With Objet’s Connex family of 3D printers, you could use one material to build the rim and spokes, and another material to encase the rim in rubber — at the same time.

“Our technology is based on inkjet technology,” says Bruce Bradshaw, director of Marketing at Objet, Ltd. “Small layers of resin are jetted to create prototypes with Objet printers. What we hang our hat on is fine details, accuracy, and high resolution that are derived from the ultra-thin layers. The fact that our customers can simulate 14 different material properties at the same time is what sets our technology apart.”

The company also has 14 cartridge-ready materials to choose from, including ABS-like rigid plastics, different grades of transparency and rubbery materials. Plus, its Connex 3D printer’s onboard software allows users to choose from 60+ materials by using the multi-material technology. Objet calls these Digital Materials. They’re made up of two Objet materials combined in specific concentrations to create a finished product that has the desired mechanical properties.

Objet At A GlanceCompany: Objet Ltd. Headquarters: Rehovot, Israel Offices: North America, Europe, Japan, China, Hong Kong, and India Year founded: 1998 Product lines: Objet Connex, Eden and Desktop families of 3D printers Materials: More than 60 Technologies: Polyjet and Polyjet Matrix Blog: It’s a 3D World |

Growth Opportunities

Bradshaw says dental, medical, education and automotive industries are prime examples of how 3D printing can improve the design process. While the automotive industry has been heavy users of AM for many years, the medical and dental industries are now seeing a huge increase in the use of AM.“The automotive industry has been very enthusiastic over our recently introduced clear material,” Bradshaw says. “It allows them to prototype reflectors, lenses — all the clear plastics used in automobiles.”

The company has seen tremendous adoption of its printers for several years, Bradshaw says. The recent publicity 3D printing is getting in mainstream media — from Jay Leno to The New York Times — doesn’t hurt.

Objet is led by its President and CEO David Reis, who has been on the Objet board since 2001. He was named to his current position in 2009. Reis, who holds economic and business degrees from Denver University, previously led Ellomay Capital Ltd., ImageID and HP Scitex.

Founded 14 years ago, Objet still sees plenty of room for growth.

“When you look at the market, out of all people who prototype, most still outsource to a service bureau because they may not realize how affordable a high-quality 3D printer is,” Bradshaw says. “A very small percentage actually own a 3D printer today, but the trend is rapidly moving toward companies investing in the technology in-house.”

To capitalize on the expanding market, Objet continues to invest heavily in 3D printing technologies, supports education initiatives and continues to expand globally.

It recently announced new appointments to its Emerging Markets division, bringing on board new regional managers for Central America, South America and Africa. With the new regional managers in place, Objet expects to boost its sales and service capabilities in these expanding markets.

Last fall, it also launched an expanded channel network across India. The new channel network includes the addition of resellers to cover larger geographical areas and continues Objet’s momentum in the Indian market following the recent appointment of Redington India as Objet’s master Indian distributor. In December, the company opened a Center of Excellence Demo Center in Chennai, India, to showcase Objet’s latest 3D printers and materials.

Products

The company targets professionals with three 3D printer lines:- The multi-material Connex line has 16-micron-layer accuracy. It includes the Objet Connex500, Connex350 and Objet260.

- The Desktop line includes the Objet24 and Objet30, with prices starting at $19,900 and accuracies of 28-micron layer thicknesses.

- Objet’s Eden family of 3D printing systems allows printing of its 14 base rigid and rubber materials also with 16-micron- layers for producing fine details. The Eden line includes the Eden500V, 350V, 260V and 250.

In addition to supporting standard STL files that can be output by CAD programs, the company has developed software plug-ins for Autodesk Inventor, SolidWorks and PTC ProEngineer.

As additive manufacturing continues to grow, Objet intends to stay ahead of the curve by proving the return-on-investment, convenience and accuracy of its multi-material technology. The company’s products don’t re-invent the wheel, but they do make it possible to print that wheel — and many other multi-material objects — all at one time.

Editor’s note: in 2012, Objet and Stratasys merged, then in 2013 the combined company acquired MakerBot.

Below you’ll find a video from the company highlighting its Connex line of 3D printers.

Sources: Interview with the company, press materials received from the company and additional information gleaned from the company’s website.

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

Jamie Gooch is the former editorial director of Digital Engineering.

Follow DE